Production tooling and spare parts for weaving machines

|

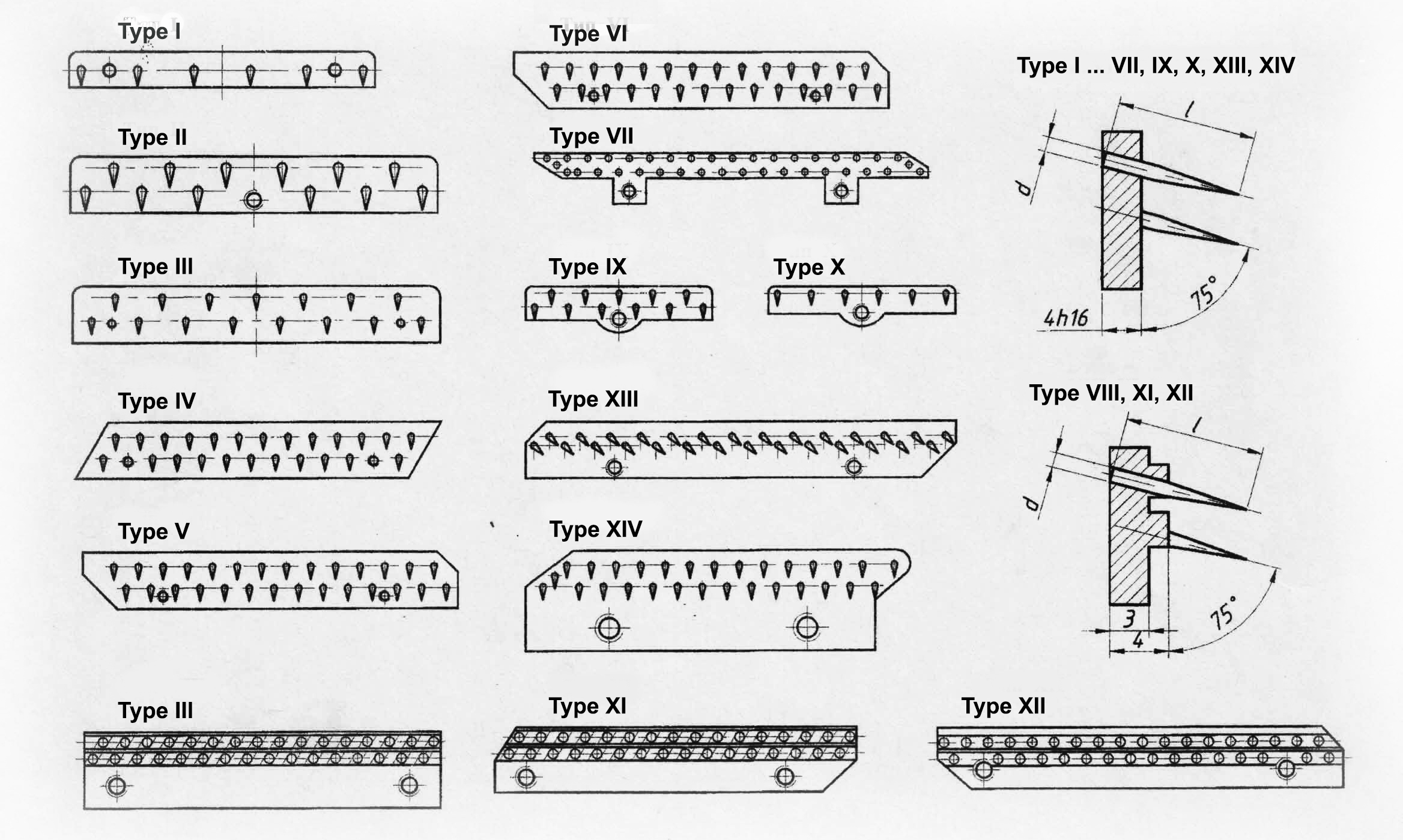

Needle type |

Industrial needle application |

|

I |

for spinning-preparatory machine combs, tentering-and-drying machine hackle bars, drawing frame hackle bars, single-/double-crank slide combs. |

|

II |

for tentering-and-drying machine needle bars. |

|

III |

for circular combs. |

|

IV |

for temple rings. |

|

V |

for cordage and rope making machines. |

|

VI |

for carding machine hackle bars, Kirschner beaters, self-acting beater. |

|

VII |

for rougher hackles. |

|

VIII |

for lattices. |

|

IX |

for blending willow and mixing bin hackle bars. |

|

X |

for garneting machine hackle bars.. |

|

XI |

for shakers and tow openers. |

|

XII |

lock plate needles for rougher hackles and drawing frame hackle bars. |

|

XIII |

lock round needles for comber hackle bars and rougher hackles. |

|

XIV |

Lock plate needles for drawing frame hackle bars. |

Available needle diameters - 0,65; 0,7; 0,8; 0.9; 1.1; 1.3; 1.5; 1.7; 2.2; 2.5; 2.8; 3.0; 3.5; 4.0; 4.5; 5.0; 5.5; 6.5; 8.0;

9.5; 10.0; 1.0 mm.

Double-pointed needles

| Needle type |

Needle diameter d , mm |

Length of set needle point l, mm |

Length L, mm |

| I | 0,9...1,8 | 8; 9; 11 | 80 |

| II | 1,6 | 3,5 |

35,5; 35,8; 36,1; 36,4; 36,7; 37,0 |

| III | 1,5 | 3,5 |

25,1; 25,5; 25,9; 26,3; 26,6; 27,0 |

|

|||

Round needles

| Needle type | Range of diameters, mm | Range of lengths, mm |  |

| I | 0,65 ... 3,5 | 10 ... 63 | |

| II | 0,8 ... 2,5 | 10 ... 19 | |

| III | 0,65 ... 1,1 | 5 ... 13 | |

| IV | 0,8; 1,1 | 3,0 ... 5,1 | |

| V | 5,0 ... 11,0 | 44 ... 320 | |

| VI | 0,9 ... 4,5 | 16 ... 44 | |

| VII | 0,7 ... 3,5 | 28 | |

| VIII | 3,0 ... 8,0 | 32 ... 75 | |

| IX | 2,5 ... 5,0 | 41 ... 85 | |

| X | 5,0 | 80 | |

| XI | 11,0 | 200 ; 320 | |

| XIII | 0,9 ... 2,2 | 22 ... 30 |

| Needle type | Gauge size, mm | Range of lengths, mm |  |

| XII |

0,64 x 1,1 0,72 x 1,45 0,93 x 1,58 |

26 | |

| XIV |

1,23 x 0,63 1,32 x 0,64 1,60 x 0,72 1,62 x 0,74 1,62 x 0,93 1,73 x 0,87 1,23 x 0,63 1,6 x 0,96 |

24; 27 24; 27 24; 27 24; 27 24; 27 24; 27 28,6 28,6

|

To purchase industrial needles, please send us a message or call us.

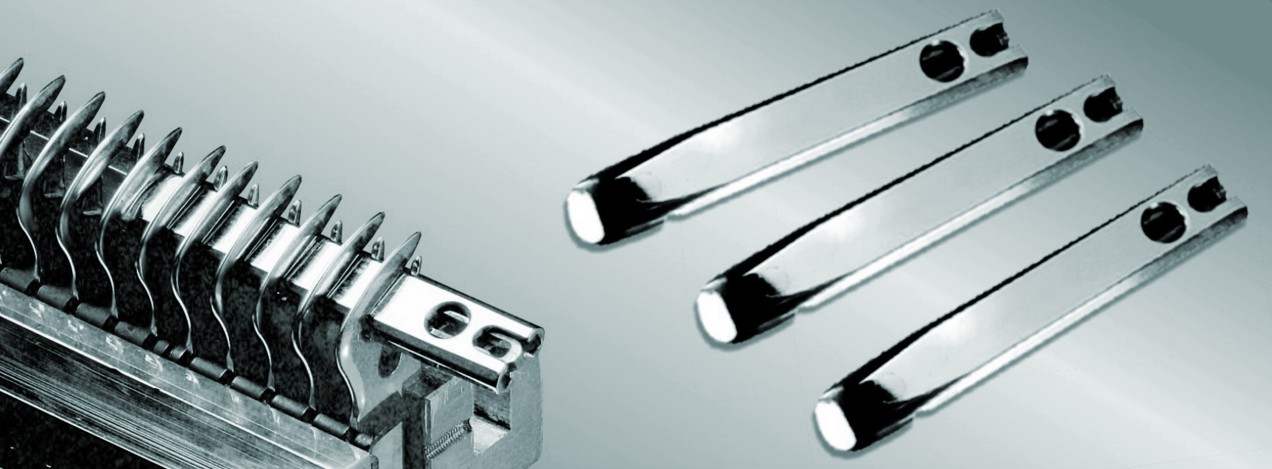

Needle bars are designed to be installed into endless pin chains of tentering-and-drying machines and used to hold fabric stretched breadthwise while passing through the drying chamber of the machine.

A wide range of needle bars is offered. The bars can be customized as well.

According to the machine design and fabric type the bars vary in shape and sizes of bar base, number of needle rows and number of needles in a row, needle sizes. Base on above-mentioned characteristics over 70 bar types are manufactured for domestic and import machines.

To purchase needle bars for tentering-and-drying machines, please send us a message or call us.

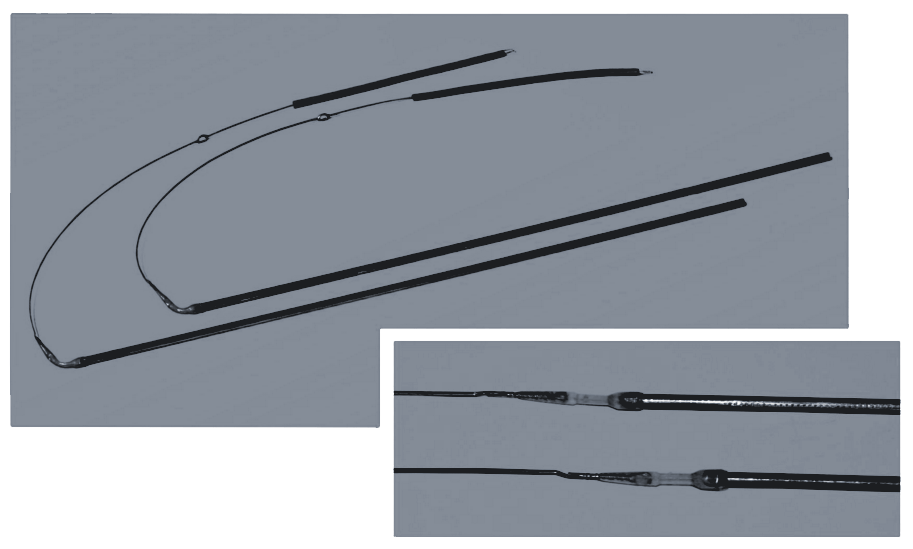

Projectiles are made of high-grade alloy steel. A seamless housing as well as a special thermal treatment both ensure a long-term operational stability and exclude a risk of housing cleavage while in operation.

Blind rivets provide a secure spring mounting to the projectile housing and allow to avoid fabric dirtying in the course of operation.

A high-grade finish and along with a fine precision manufacture both assure a machine operational stability at high speeds.

The projectiles are equipped with flat jaw springs and holes in clamping surfaces.

|

Clamping force, H |

Application |

Linear density, tex |

|

from 14 up to 18 |

synthetic silk |

up to 25 |

|

above 18 up to 22 |

cotton |

up to 25 |

|

above 22 to 26 |

cotton flax |

up to 70 |

|

above 26 to 30 |

wool |

up to 200 |

It is possible to deliver bodies and grippers separately.

To purchase projectiles, please send us a message or call us.

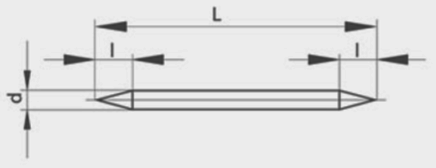

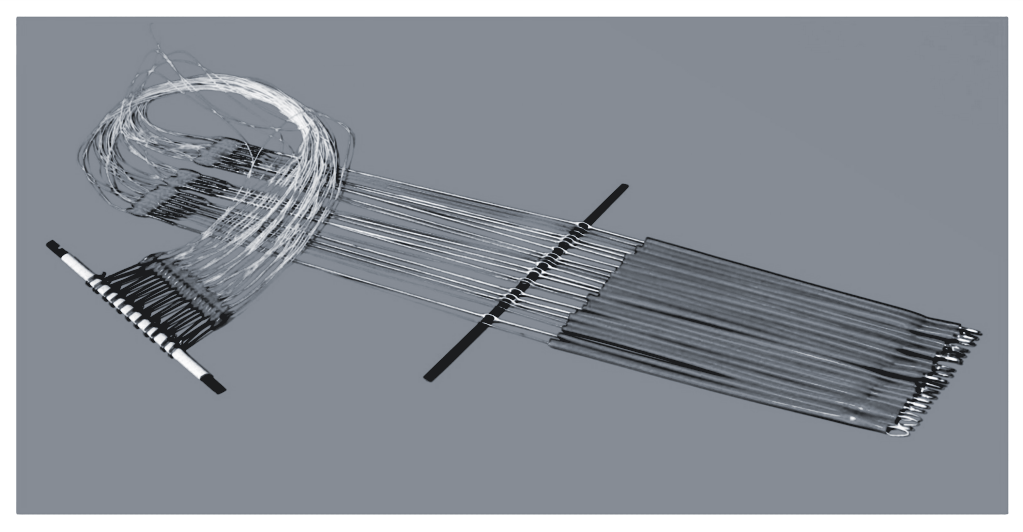

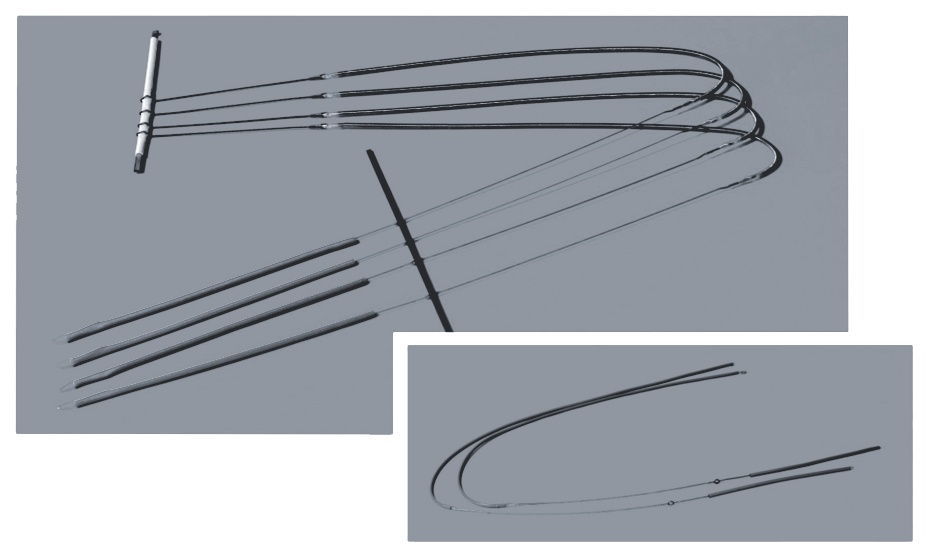

A premier choice of production tooling ensuring both a proper shed opening and a required hook return force provides a proper operation of entire Jacquard machine

Jacquard healds can be optionally supplied with different return elements as follows:

- metal suspension

- elastic element

- spring element

Jacquard healds with metal suspension are of long-term service, durable, and reliable. They are mainly used for low-speed ordinary looms with high loom fly forming.

Jacquard healds with elastic element are used for medium-speed weaving machines as well as weaving high-density fabrics. They are easy maintainable and affordable.

Jacquard healds with spring element are optimized for higher requirements at high operating speeds and different loads. They can be manufactured in the modifications as follows: healds with open spring or in loom fly protective housing.

To purchase jacquard healds, please send us a message or call us.

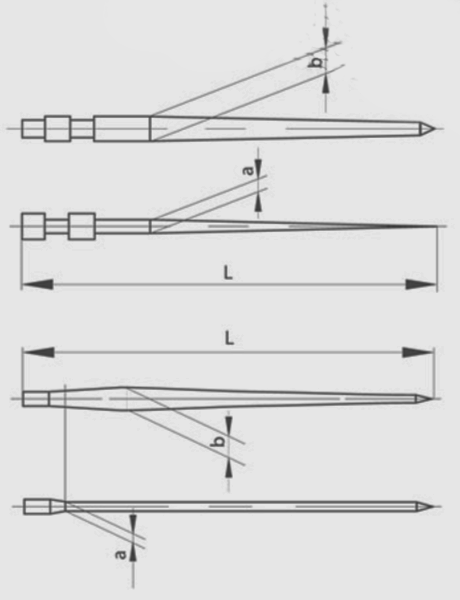

|

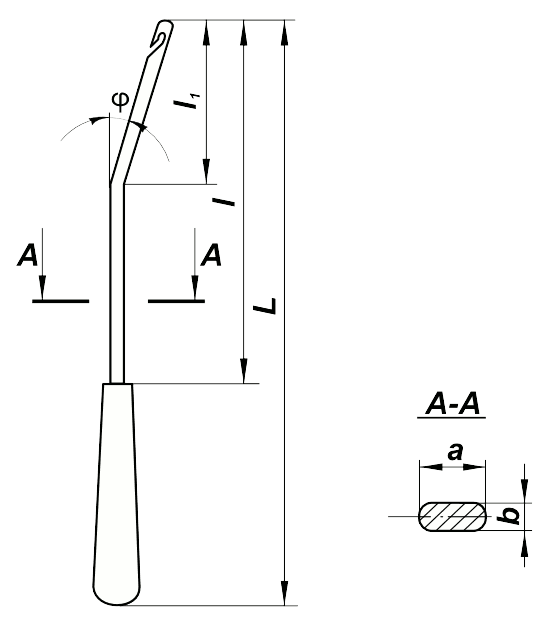

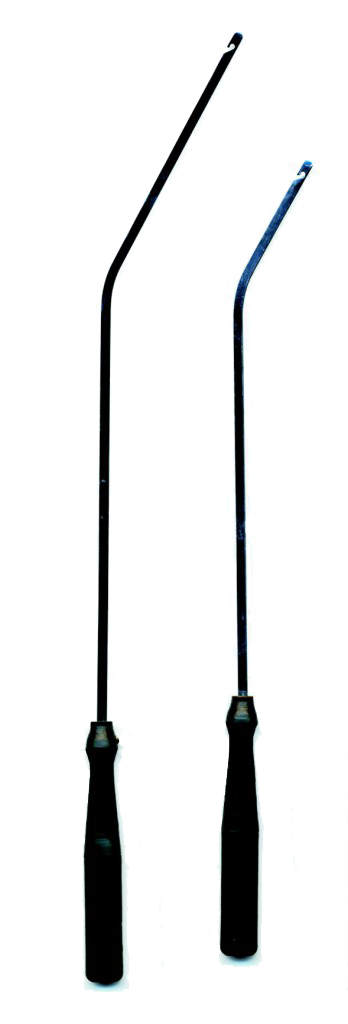

Parameters of weaving hook for warp yarn threading into a reed |

|

|

Overall hook length, L, mm |

160-350 |

|

Blade length, l, mm |

100-290 |

|

Hook working part, l1 , mm

|

40-80 |

|

Hook inclination, φ,grad |

0-30 |

|

Blade width, a, mm |

3,0; 4,0 |

|

Blade thickness, b, mm |

0,8; 1,0 |

We are ready to consider your offers to modify hook design and sizes.

To purchase weaving hooks for warp yarn threading into a reed, please send us a message or call us.