Production tooling and spare parts for non-woven fabric manufacture

Felting needles play an important part in manufacturing non-woven products. Choosing the right type of needles is critical. The working blade of precise and appropriate gauge as well as an optimum design and precise location of barbs allow to achieve desired properties of non-woven products as well as their quality.

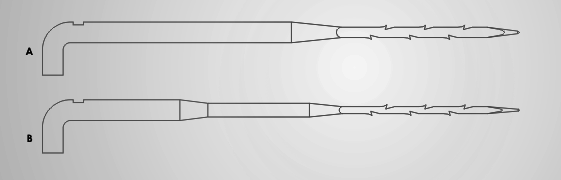

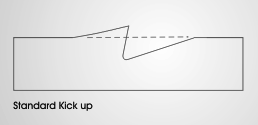

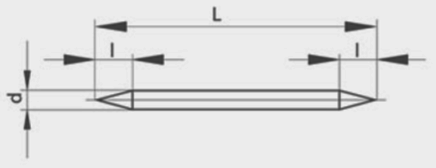

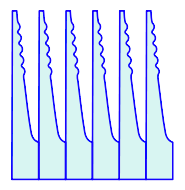

Felting needles come as single-reduced (Fig. A.) or double-reduced (Fig. B.) types.

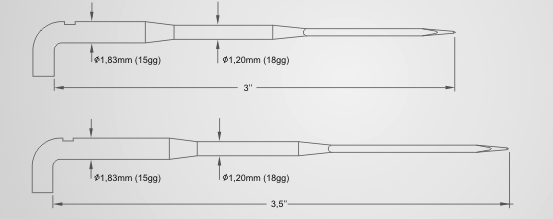

Shank and needle length

The most commonly used diameter of the shank is 1.83 mm (15-gauge).

The intermediate shank diameter of double-reduced needle is 1.20 mm (18-gauge) and 1.50 mm (16-gauge).

The needles of the following length are mainly and mostly offered:

- 3-inch needles (76.2 mm);;

- 3.5-inch needles (88.9 mm).

The needle length is measured from the point to the inner edge of the needle crank.

Barb types:

- Conventional cut barbs;

- F-Barbs, protecting fibers.

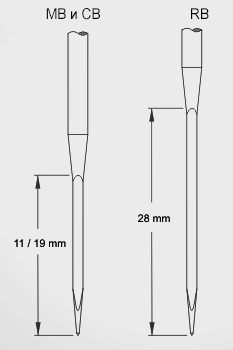

Distances between barbs:

- RB (Regular Barb) = 6.3 mm;

- MB (Medium Barb) = 4.8 mm;

- CB (Close Barb) = 3.3 mm;

Working blade length

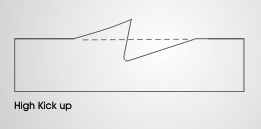

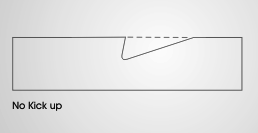

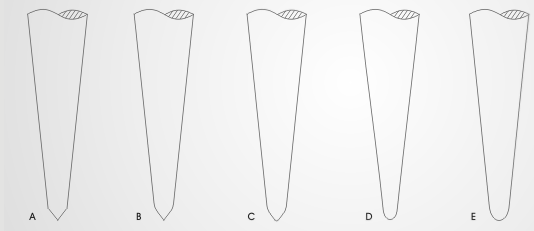

Felting needle barb shapes:

- High Kick up;

- Standard Kick up;

- No Kick up.

Felting needle point types

A - standard point,

B - polished point,

C - slightly rounded point,

D - medium rounded point,

E - rounded point.

The following needles can be also manufactured:

- crown needles , with three bards, located on the same height on a short working blade;

- Vario Barb needles, with barbs depth and kick up, increased from the point of the needle towards the shank.

To purchase felting needles, please send us a message or call us.

Base:

5-layer or 6-layer with cured rubber layer (thickness 0,50 mm)

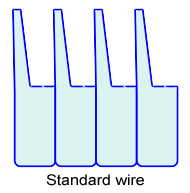

Wire: round, bright.

Strip size:

- base - 265,00 х 80,00 mm

- wire setting - 253,00 х 63,50 mm

To purchase cleaning strips, please send us a message or call us.

|

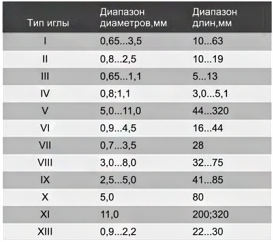

Тип иглы |

Назначение игл технических |

|

I |

Для гребней приготовительно прядильных машин, планок сушильно - ширильных машин, планок гребенных для ленточных машин, гребней скользящих одно-, двух-кривошипных. |

|

II |

Для планок сушильно - ширильных машин. |

|

III |

Для круглых гребней. |

|

VI |

Для колец шпаруток. |

|

V |

Для машин канатного производства. |

|

VI |

Для планок чесальных машин, игольчатых трепал, волчка периодического действия. |

|

VII |

Для планок льночесальных машин. |

|

VIII |

Для планок транспортерных решеток. |

|

IX |

Для планок смесовых машин и лабазов. |

|

X |

Для планок машины "Рвач". |

|

XI |

Для трясильных и куделеприготовительных машин. |

|

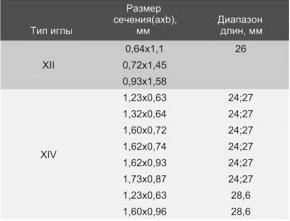

XII |

Иглы плоские с замком для планок льночесальных машин и гребенных планок ленточных машин. |

|

XIII |

Иглы круглые с замком для планок гребенных и льночесальных машин. |

|

XIV |

Иглы плоские с замком для планок ленточных машин. |

Иглы изготавливаются c диаметром - 0,65; 0,7; 0,8; 0.9; 1.1; 1.3; 1.5; 1.7; 2.2; 2.5; 2.8; 3.0; 3.5; 4.0; 4.5; 5.0; 5.5; 6.5; 8.0; 9.5; 10.0; 1.0 мм.

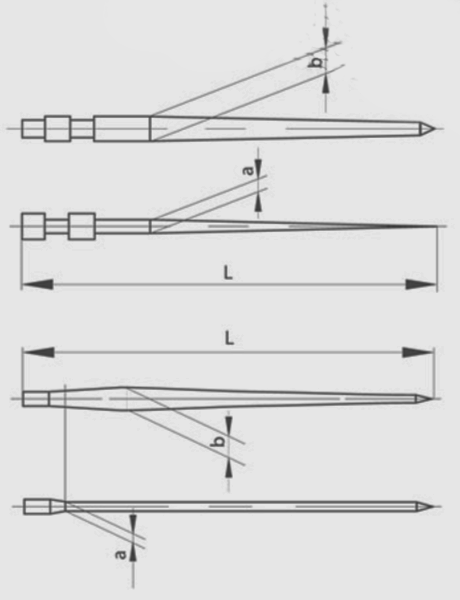

Иглы двухконечные

Иглы круглые

Иглы плоские

Чтобы купить иглу техническую, напишите или позвоните нам.

To process wool we suggest topping Morel’s rollers with nonuniformaly variable pitch wire clothings.

The wire clothing of such design will allow:

- to ease a wire clothing setup by replacing two previously used wire clothings with a single one;

- to increase a waste removal quality.

To process synthetic fiber we suggest using wire clothing with fluted surface dent.

The use of the said wire clothing at the doffing drum will allow you to increase the output of carding machine owing to the wire clothing feature enabling to hold fabric in carding area.

Tooling improvement is a core principal to ensure steady operation of enterprise.

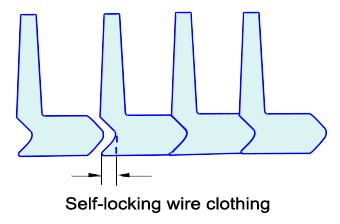

The wire clothing setup into the unit allows:

- to top rollers over worn grooves;

- to avoid ribbon unwinding at swifts in case of intrusion of foreign matter into carding area.

Dear Customers!

To reduce waste of wire clothing produced while topping driven elements of carding machines it is reasonable to place an order for wire clothing specifying the quantity not in kilograms but in meters. This will reduce your expenses.

To calculate required quantity in meters, please use the formula as follows:

where: М — quantity of wire clothing, m

П — 3,1415926

D — swift diameter, mm

L — swift width, mm

В — thickness of wire clothing base, mm or spacing of swift groove, mm

To purchase a self-locking wire clothing, please send us a message or call us.

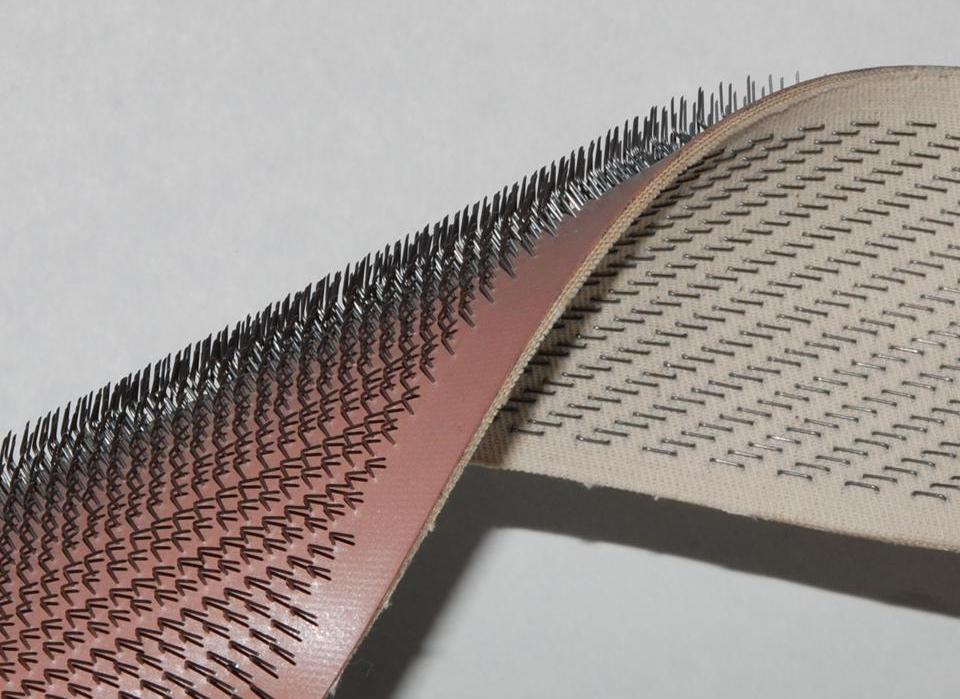

The card filleting is designed for topping opening parts of carding machines, used in spinning industry. It consists of a flexible base where steel wire spikes with edged tips, normally base bending, are slantwise fixed.

Width — 22-24 mm.

Triple-layer twill base with rubber cushion.

ДCramp needle diameter - 0.28 mm.

To purchase a card filleting, please send us a message or call us.