Compound needle

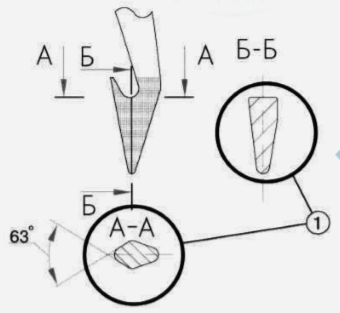

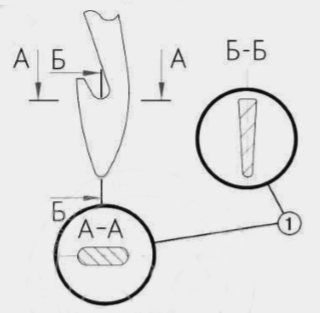

COMPOUND NEEDLE, items 0-407

KEY DIFFERENCES OF THE NEEDLE, MANUFACTURED APPLYING AN OLD AND NEW TECHNOLOGY.

|

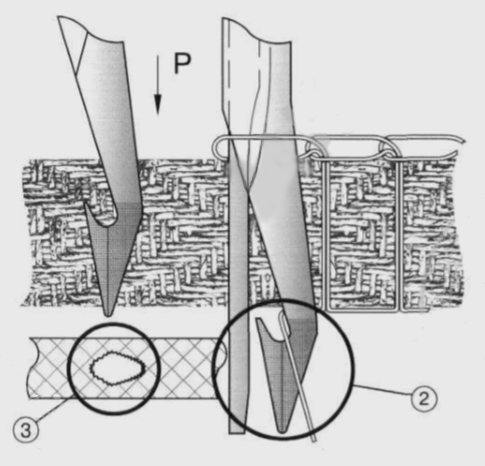

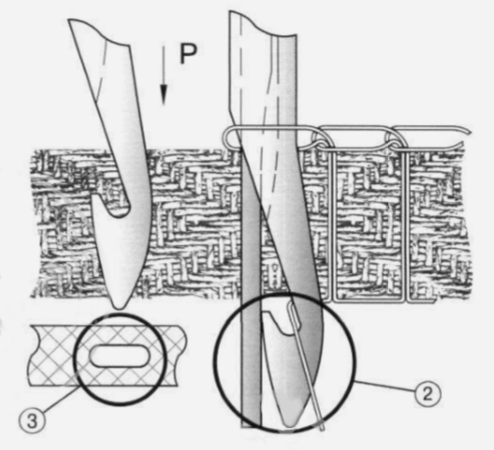

Needle point, manufactured applying an old technology

1. A hand hook sharpening does not provide a required precision of needle hook dimensions, 2. A hook sharpening is carried out after hardening and polishing therefore the hook of finished needled is scale- olored. The gap while closing leads to lint accumulation hampering a tongue slide inside a needle body. The punching force P comes up to 250 g. 3. While punching the needle pierces through a fabric tearing up fibers and forming torn edges.

|

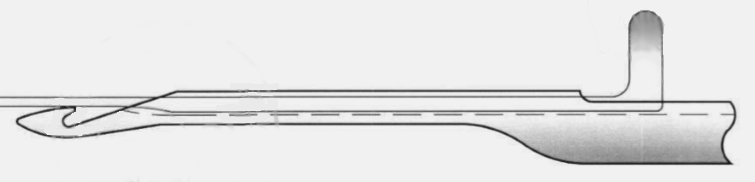

Needle point, manufactured applying a new technology

1. A hook sharpening automation provides uniform needle hook dimensions. 2. A hook surface is light-colored, scale-free. No gap while closing leads to improve a needle performance. The punching force Р comes up to 100 g. 3. While punching the needle easily penetrates into a fiber drawing aside fibers.

|

To purchase a compound needle, please send us a message or call us.